Expertise and Global Reach in Plastic Machinery Manufacturing

Table of Contents

Expertise, Innovation, and Global Presence in Plastic Machinery #

Matila Industrial Co., Ltd. has been a cornerstone of the Taiwanese plastic machinery sector since its establishment in 1988. With decades of experience, Matila has become a leading provider of complete plastic bag manufacturing plants, offering a diverse portfolio of machinery and solutions tailored to the evolving needs of the plastics industry.

Company Background and Milestones #

Founded in 1988, Matila Industrial Co., Ltd. quickly established itself as a trusted manufacturer of plastic processing equipment. In 1999, the company expanded its capabilities by building its own production facility, enabling in-house manufacturing of blown film machines and recycling equipment. This strategic move enhanced Matila’s competitiveness and allowed for greater innovation and quality control.

Over the years, Matila has consistently invested in research and development, resulting in a broad range of advanced machinery. Notable achievements include the development and production of HDPE, LDPE, and LLDPE blown film machines with diameters ranging from 25 mm to 120 mm. In 2003, Matila introduced two-color (stripe line) and double-layer co-extrusion lines for industrial stretch wrapping film. By 2014, the company had launched a comprehensive series of blown film machines utilizing advanced technology, capable of producing HDPE, LDPE, LLDPE, and PP films with widths from 22.5 cm up to 10 meters. Among its innovations is the fabrication of the largest three-layer co-extrusion rotary die head, with a die diameter reaching 1.2 meters.

Product Portfolio #

Matila’s product range encompasses:

- Blown Film Machines

- Plastic Waste Recycling Machines

- Twin Screw Co-Rotary Extrusion Machines

- Bags Making Machines

- Flexographic Printing Machines

The plastic recycling lines are equipped with comprehensive washing, crushing, and pelletizing systems, supporting capacities from 200 kg to 800 kg per hour. For smaller-scale operations, Matila offers mini-type recycling solutions for industrial waste, with capacities ranging from 30 kg to 150 kg per hour.

The twin screw extruders feature flexible configurations, suitable for compounding colored masterbatch, CaCO3, and other additives. These machines can handle up to 82% CaCO3 filler, providing a wide array of recycling and compounding solutions to meet diverse customer requirements.

Partnerships and Quality Assurance #

Matila has cultivated long-term partnerships with reliable suppliers of bag making and flexographic printing machines, some spanning over 20 years. This collaboration ensures that customers receive products characterized by high efficiency and consistent quality.

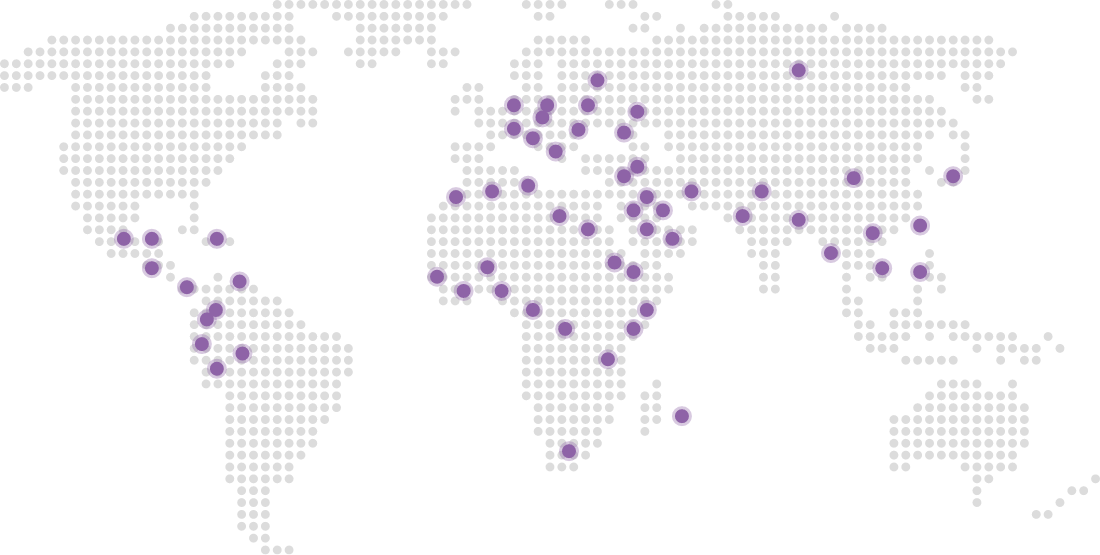

Global Market Presence #

Matila’s commitment to quality and innovation has earned it a strong reputation in international markets. The company has successfully delivered machinery and solutions to clients in numerous countries, including Algeria, Bangladesh, Bolivia, Belarus, Bulgaria, Congo, Chile, China, Colombia, Costa Rica, Croatia, Czech Republic, Djibouti, Ecuador, Egypt, El Salvador, Ethiopia, Ghana, Greece, Guatemala, Haiti, Hungary, Iran, Iraq, Ivory Coast, Japan, Kenya, Saudi Arabia, Kuwait, Latvia, Libya, Liberia, Lithuania, Morocco, Mexico, Myanmar, Mozambique, Mauritius, Nigeria, Oman, Pakistan, Peru, Philippines, Poland, Romania, Russia, South Africa, Sierra Leone, Slovenia, Sudan, Tanzania, Taiwan, Thailand, Turkey, Tunisia, UAE, Ukraine, Venezuela, Vietnam, and Serbia.

Contact Information #

- Company: Matila Industrial Co., Ltd

- Address: No. 186, Zhongxiao Road, Bali District, New Taipei City, Taiwan 24944

- TEL: +886-2-2619-2222

- FAX: +886-2-2610-1100

- E-Mail: matila@matila.com.tw